Premium Alloy Steel Bar Manufacturer in Kolkata: Complete Guide

Introduction to Alloy Steel Bars: Engineering Excellence from Kolkata

In the world of industrial manufacturing and infrastructure development, alloy steel bars represent the critical backbone of countless applications where standard carbon steel simply cannot meet performance requirements. As a premier alloy steel bar manufacturer in Kolkata, Usha Metal Industries has established itself as an industry leader in producing these essential materials that combine strength, durability, and specialized properties.

What Defines Alloy Steel Bars?

Alloy steel bars are specialized steel products containing specific percentages of elements beyond the basic carbon-iron mixture. These carefully formulated additions—including chromium, nickel, molybdenum, vanadium, and manganese—create materials with enhanced properties such as:

- Superior tensile strength (typically 30-150% higher than carbon steel)

- Enhanced hardness (up to 60 HRC after heat treatment)

- Improved corrosion resistance in challenging environments

- Better fatigue resistance under cyclic loading conditions

- Higher temperature performance in extreme operating conditions

- Enhanced machinability for precision manufacturing

Kolkata: Eastern India's Steel Manufacturing Hub

Kolkata has emerged as a strategic center for alloy steel production in Eastern India due to several key advantages:

- Strategic location: Proximity to Haldia and Kolkata ports facilitates efficient import of alloying elements and export of finished products

- Robust transportation network: Excellent rail, road, and waterway connectivity

- Skilled workforce: Generations of metallurgical expertise and technical knowledge

- Industrial ecosystem: Supporting industries including heat treatment facilities, testing laboratories, and machining centers

- Technical institutions: Proximity to metallurgical research centers and engineering colleges

These advantages enable alloy steel manufacturers in Kolkata to deliver exceptional quality at competitive prices, serving not only Eastern India but also neighboring countries including Nepal, Bhutan, Bangladesh, and beyond.

Types of Alloy Steel Products & Grades Available in Kolkata

The alloy steel bar industry in Kolkata produces a diverse range of products to meet specific engineering requirements across multiple sectors. These products vary in shape, size, composition, and mechanical properties.

Alloy Steel Round Bars: The Industry Workhorse

Alloy steel round bars represent the most commonly produced profile, available in various processing conditions:

- Hot-rolled round bars: Diameter range 10mm-500mm, suitable for general engineering applications

- Cold-drawn round bars: Diameter range 5mm-250mm, offering tighter tolerances and improved surface finish

- Forged round bars: Diameter range 50mm-1000mm, providing superior internal structure for critical applications

- Bright bars: Precision ground and polished for applications requiring exact dimensions

Common Alloy Steel Round Bar Grades in Kolkata

| Grade | Equivalent Standards | Key Properties | Primary Applications |

|---|---|---|---|

| EN8 | AISI 1040, C40 | Medium carbon steel with good tensile strength | General engineering, shafts, gears |

| EN19 | AISI 4140, 42CrMo4 | Chromium-molybdenum alloy with high strength | Heavy-duty shafts, gears, automotive components |

| EN24 | AISI 4340, 40NiCrMo7 | Nickel-chromium-molybdenum with excellent toughness | Aircraft components, heavy machinery, power transmission |

| EN31 | AISI 52100, 100Cr6 | High carbon chromium with excellent wear resistance | Bearings, precision tooling, measuring instruments |

| SAE 8620 | 21NiCrMo2, 20NiCrMo2-2 | Nickel-chromium-molybdenum case hardening steel | Gears, camshafts, crankshafts |

Flat and Square Bars: Structural Excellence

Alloy steel flat bars and square bars from Kolkata manufacturers offer versatility for structural and machine-building applications:

- Flat bars: Thickness 5-100mm, width 20-600mm, for heavy engineering and construction

- Square bars: Dimensions 10-200mm, ideal for machine building and tooling applications

These profiles are available in various alloy grades including EN series, SAE/AISI specifications, and tool steel variants, meeting international standards like ASTM A29, EN 10083, and IS 4432.

Specialized Profiles and Custom Products

Beyond standard shapes, alloy steel manufacturers in Kolkata produce specialized profiles to meet specific industry requirements:

- Hexagonal bars: For fasteners, fittings, and precision engineering components

- Octagonal bars: For specialized tooling applications

- Custom-shaped sections: Produced through forging or extrusion for specific applications

- Pre-machined components: Semi-finished parts ready for final machining

Key Industrial Applications of Alloy Steel Bars

The versatility and enhanced properties of alloy steel bars make them indispensable across numerous industries:

Automotive and Transportation

- Powertrain components: Crankshafts, connecting rods, transmission gears

- Suspension systems: Torsion bars, coil springs, stabilizer bars

- Steering mechanisms: Steering knuckles, tie rods, steering columns

- Safety-critical parts: Axle shafts, chassis components, brake system parts

Heavy Engineering and Construction

- Infrastructure projects: Bridge components, high-rise building reinforcements

- Heavy machinery: Excavator components, crane parts, mining equipment

- Railway applications: Rail fastening systems, bogie components, axles

- Material handling equipment: Lifting hooks, chains, conveyor components

Energy Sector

- Power generation: Turbine components, generator shafts, boiler parts

- Oil and gas: Drilling equipment, pressure vessels, pipeline components

- Renewable energy: Wind turbine components, hydroelectric equipment

- Nuclear applications: Specialized components requiring exceptional reliability

Tool and Die Manufacturing

- Cutting tools: Drills, milling cutters, lathe tools

- Forming dies: Stamping dies, forging dies, extrusion dies

- Plastic molds: Injection molding tools, compression molds

- Measuring instruments: Gauges, fixtures, and precision tools

The diverse applications highlight why alloy steel bar suppliers in Kolkata must maintain stringent quality standards and offer a wide range of grades and specifications to meet industry requirements.

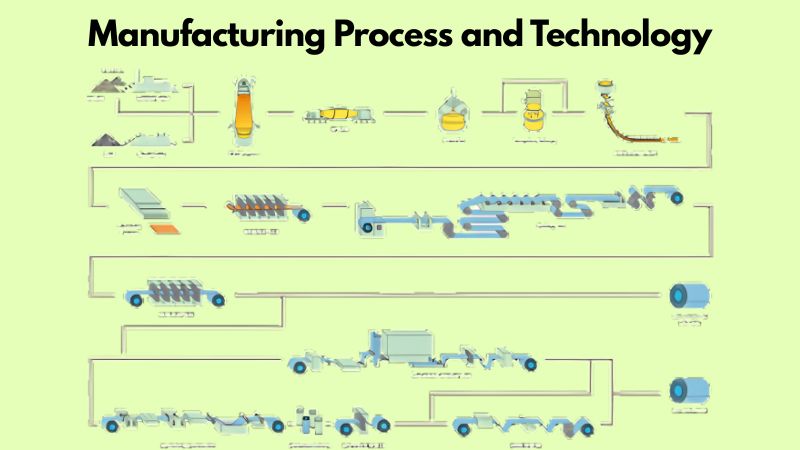

Manufacturing Process and Technology

The production of high-quality alloy steel bars involves a sophisticated multi-stage process that combines metallurgical expertise with advanced manufacturing technology:

1. Raw Material Selection and Preparation

The manufacturing process begins with careful selection of raw materials:

- Primary steel: High-purity iron ore or recycled steel scrap

- Alloying elements: Precise additions of chromium, nickel, molybdenum, vanadium, etc.

- Fluxing agents: Materials that remove impurities during melting

2. Melting and Refining

Modern alloy steel manufacturers in Kolkata utilize advanced melting technologies:

- Electric Arc Furnaces (EAF): Primary melting at temperatures exceeding 1600°C

- Ladle Metallurgy Furnace (LMF): Secondary refining for precise composition control

- Vacuum Degassing (VD): Removal of gases to improve steel quality

- Electroslag Remelting (ESR): For ultra-high purity alloy steels

3. Casting and Primary Forming

The molten alloy steel is then cast into semi-finished forms:

- Continuous casting: Producing billets, blooms, or slabs

- Ingot casting: For larger sections or specialized alloys

- Primary hot working: Initial shaping through forging or rolling

4. Secondary Processing

The semi-finished products undergo further processing to achieve final dimensions:

- Hot rolling: Shaping at temperatures above recrystallization (850-1250°C)

- Forging: Precision shaping using hydraulic or mechanical presses

- Cold drawing: Producing precise dimensions and improved surface finish

- Turning and grinding: For bright bars with tight tolerances

5. Heat Treatment

Critical heat treatment processes enhance the mechanical properties:

- Annealing: Stress relief and improved machinability

- Normalizing: Refined grain structure and uniform properties

- Quenching and tempering: Optimized hardness and toughness

- Solution treatment: For specialized stainless and tool steel grades

6. Quality Control and Testing

Comprehensive testing ensures compliance with specifications:

- Chemical analysis: Spectrographic testing for composition verification

- Mechanical testing: Tensile, impact, and hardness testing

- Non-destructive testing: Ultrasonic, magnetic particle, and eddy current inspection

- Microstructure analysis: Metallographic examination

- Dimensional inspection: Ensuring compliance with size tolerances

Leading alloy steel bar manufacturers in Kolkata like Usha Metal Industries have invested in state-of-the-art equipment and rigorous quality management systems to ensure consistent product quality meeting international standards.

Quality Standards and Certification

Alloy steel bar suppliers in Kolkata adhere to stringent quality standards to ensure product reliability:

Indian Standards

- IS 4432: Specification for alloy steel forgings for general industrial use

- IS 1570: Schedules for wrought steels for general engineering purposes

- IS 1875: Carbon and alloy steel billets, blooms, slabs, and bars for forgings

- IS 7291: Specification for high tensile alloy steel bars

International Standards

- ASTM A29/A29M: Standard specification for steel bars, carbon and alloy

- ASTM A193/A193M: Specification for alloy-steel bolting materials

- EN 10083: European standard for quenched and tempered steels

- SAE J404: Chemical compositions of SAE alloy steels

- DIN 17200: German standard for heat-treatable steels

Quality Management Certifications

- ISO 9001:2015: Quality management system certification

- ISO 14001: Environmental management system

- OHSAS 18001/ISO 45001: Occupational health and safety

- BIS Certification: Bureau of Indian Standards compliance

These certifications ensure that alloy steel products from Kolkata meet the highest quality standards and can be used with confidence in critical applications worldwide.

Advantages of Sourcing Alloy Steel from Kolkata

Choosing a Kolkata-based alloy steel bar manufacturer offers several strategic advantages:

Strategic Location and Logistics

- Port proximity: Easy access to Kolkata and Haldia ports for import/export

- Transportation network: Excellent rail, road, and inland waterway connectivity

- Regional hub: Strategic position for serving Eastern India, Nepal, Bhutan, Bangladesh

- Warehousing facilities: Modern storage infrastructure for just-in-time delivery

Manufacturing Excellence

- Technical expertise: Generations of metallurgical knowledge and experience

- Modern equipment: State-of-the-art melting, forming, and testing facilities

- Quality focus: Rigorous quality management systems and certifications

- R&D capabilities: Continuous improvement and material innovation

Commercial Benefits

- Competitive pricing: Efficient operations and healthy market competition

- Flexible order quantities: Ability to serve both large and small volume requirements

- Customization options: Tailored products to meet specific requirements

- Value-added services: Heat treatment, machining, and testing services

Technical Support

- Material selection guidance: Expert advice on grade selection

- Engineering consultation: Technical support for application challenges

- Quality documentation: Comprehensive test certificates and traceability

- After-sales support: Responsive technical assistance

How to Select the Right Alloy Steel Bar Supplier in Kolkata

When evaluating alloy steel bar manufacturers in Kolkata, consider these critical factors:

Manufacturing Capabilities Assessment

- Production facilities: Modern equipment and advanced manufacturing processes

- Product range: Comprehensive offering of grades, sizes, and profiles

- Production capacity: Ability to handle your volume requirements

- Special processing: Heat treatment, machining, and finishing capabilities

Quality Assurance Systems

- Quality certifications: ISO 9001:2015 and industry-specific certifications

- Testing facilities: In-house laboratories for chemical and mechanical testing

- Inspection procedures: Comprehensive quality control at each production stage

- Traceability systems: Batch tracking and documentation

Industry Experience and Reputation

- Track record: Years of experience in your specific industry

- Client references: Feedback from existing customers in similar applications

- Industry recognition: Awards, certifications, and memberships

- Case studies: Successful projects and problem-solving examples

Commercial and Service Factors

- Pricing structure: Competitive and transparent pricing

- Delivery reliability: Consistent on-time delivery performance

- Technical support: Access to metallurgical expertise

- After-sales service: Responsive problem resolution

- Financial stability: Ensuring long-term partnership potential

By thoroughly evaluating these factors, you can select a reliable alloy steel bar supplier in Kolkata that will serve as a valuable partner for your manufacturing or construction projects.

Frequently Asked Questions About Alloy Steel Bars

What is the difference between carbon steel and alloy steel bars?

Carbon steel contains primarily iron and carbon (up to 2.1%), while alloy steel incorporates additional elements like chromium, nickel, molybdenum, and vanadium in specific percentages to enhance properties such as strength, hardness, wear resistance, and corrosion resistance. Alloy steels typically offer superior performance in demanding applications where carbon steel would fail.

How do I determine which alloy steel grade is right for my application?

Selecting the appropriate alloy steel grade depends on several factors including mechanical property requirements (tensile strength, hardness, toughness), operating environment (temperature, corrosion exposure), manufacturing processes (machinability, weldability, heat treatment response), and cost considerations. Consulting with a metallurgist or technical expert from a reputable alloy steel manufacturer is recommended for optimal material selection.

What testing is performed on alloy steel bars to ensure quality?

Quality testing for alloy steel bars typically includes chemical composition analysis (spectrographic testing), mechanical property testing (tensile, hardness, impact), non-destructive testing (ultrasonic, magnetic particle inspection), microstructure examination, and dimensional verification. Reputable manufacturers provide comprehensive test certificates documenting these results for each batch or heat number.

What are the most common heat treatments for alloy steel bars?

Common heat treatments include annealing (to improve machinability and reduce hardness), normalizing (to refine grain structure), quenching and tempering (to achieve optimal hardness and toughness balance), case hardening (for surface hardness with tough core), and stress relieving (to remove internal stresses). The specific heat treatment depends on the alloy composition and intended application.

How do alloy steel bars from Kolkata compare to imported alternatives?

Alloy steel bars manufactured in Kolkata offer comparable quality to imported alternatives while providing advantages such as shorter lead times, lower logistics costs, easier communication, flexibility in order quantities, and responsive technical support. Leading Kolkata manufacturers maintain international quality standards and certifications while offering competitive pricing.

Conclusion: Partnering with the Right Alloy Steel Bar Manufacturer

Kolkata has firmly established itself as a premier center for alloy steel bar manufacturing in Eastern India. The city's strategic location, industrial ecosystem, technical expertise, and quality focus make it an ideal sourcing destination for critical alloy steel components across diverse industries.

When selecting an alloy steel bar supplier in Kolkata, look beyond just price to evaluate manufacturing capabilities, quality systems, technical expertise, and service reliability. The right supplier will serve as a valuable partner, providing not just materials but also technical support and solutions that contribute to your project's success.

At Usha Metal Industries Private Limited, we combine decades of metallurgical expertise with modern manufacturing technology to deliver premium quality alloy steel bars that meet the most demanding specifications. Our comprehensive range of products, rigorous quality control, and responsive customer service have made us a preferred partner for industries across India and beyond.

This comprehensive guide was developed by the metallurgical experts at Usha Metal Industries Private Limited, a leading alloy steel bar manufacturer in Kolkata with over two decades of experience serving diverse industries.

Need Premium Alloy Steel Bars for Your Project?

Contact our technical team for personalized assistance with material selection, specifications, and competitive quotations.

Request a QuoteCall us directly: +91 9903302674