GI Earthing Pipes in Kolkata

Table of Contents

- Introduction to GI Earthing Pipes

- Types of GI Earthing Pipes Available in Kolkata

- Manufacturing Process of GI Earthing Pipes

- Applications of GI Earthing Pipes

- Advantages of GI Earthing Pipes

- How to Choose the Right GI Earthing Pipe

- Why Choose Usha Metals as Your GI Earthing Pipes Supplier

- Frequently Asked Questions

- Conclusion

Understanding GI Earthing Pipes: Kolkata's Premier Electrical Safety Solution

Galvanized Iron (GI) earthing pipes represent specialized conductive conduits that undergo hot-dip galvanization, creating a protective zinc shield that combats corrosion while maintaining optimal electrical conductivity. At Usha Metals, we've positioned ourselves as the foremost GI earthing pipes supplier in Kolkata, delivering exceptional electrical grounding solutions throughout Eastern India's expanding infrastructure landscape.

The Essence of GI Earthing Technology

These specialized earthing components form the foundation of reliable electrical grounding networks, creating secure pathways for fault current dissipation. The metallurgical zinc bonding achieved through hot-dip galvanization shields the core material from soil-based degradation even in challenging environmental conditions. This engineering approach ensures sustained conductivity and system integrity throughout the installation's operational lifespan, making these components indispensable in comprehensive electrical safety frameworks.

Market demand for best GI earthing pipes in Kolkata has seen remarkable growth as safety regulations tighten and awareness increases across industrial, commercial and residential sectors. As a dedicated GI earthing pipe manufacturer in Kolkata, our production protocols strictly adhere to IS:3043 earthing system standards and IS:2629 hot-dip galvanization specifications, ensuring regulatory compliance and performance reliability.

Kolkata's Strategic Position in Earthing Solutions

The city has developed into a pivotal manufacturing hub for GI earthing pipe production in Eastern India, benefiting from several regional advantages:

- Logistical connectivity: The proximity to Haldia and Kolkata port facilities streamlines raw material acquisition and finished product distribution

- Multi-modal transport infrastructure: Comprehensive rail, road, and waterway networks facilitate efficient nationwide delivery

- Technical expertise: A heritage of metallurgical craftsmanship combined with specialized electrical safety knowledge

- Complementary industrial sectors: Access to advanced galvanizing operations, testing facilities, and certification authorities

- Educational resources: Collaboration with electrical engineering research institutions and technical education centers

This confluence of advantages enables GI earthing pipe manufacturers in Kolkata like Usha Metals to engineer superior earthing solutions at accessible price points, supporting vital electrical infrastructure development across India and neighboring regions.

Types of GI Earthing Pipes Available in Kolkata

As a premier GI earthing pipes supplier in Kolkata, we offer a comprehensive range of earthing solutions to meet diverse electrical safety requirements:

Based on Manufacturing Process:

- ERW (Electric Resistance Welded) GI Earthing Pipes: Manufactured by cold-forming steel into a tubular shape and welding the seam using electric resistance welding before hot-dip galvanization. These are the most common type used in standard earthing applications.

- Seamless GI Earthing Pipes: Produced without any welding seam, offering superior strength and conductivity for critical installations like power plants and high-voltage substations.

Based on Thickness & Diameter:

- Standard Earthing Pipes (40mm diameter): The most commonly used size for residential and light commercial applications.

- Medium-Duty Earthing Pipes (50mm diameter): Preferred for commercial buildings, industrial facilities, and medium-voltage applications.

- Heavy-Duty Earthing Pipes (80-100mm diameter): Designed for high-voltage substations, power plants, and telecommunications infrastructure.

Common GI Earthing Pipe Specifications in Kolkata

- Residential Applications: 25mm diameter, 2.0-3.0m length, 3.25mm wall thickness, 80-120 microns zinc coating

- Commercial/Residential: 40mm diameter, 2.0-3.0m length, 3.65mm wall thickness, 80-120 microns zinc coating

- Industrial/Commercial: 50mm diameter, 2.5-3.0m length, 3.85mm wall thickness, 100-150 microns zinc coating

- Heavy Industrial: 80mm diameter, 3.0m length, 4.05mm wall thickness, 120-150 microns zinc coating

- Substations/Power Plants: 100mm diameter, 3.0m length, 4.50mm wall thickness, 120-150 microns zinc coating

Based on Coating Types:

- Standard Hot-Dip Galvanized Earthing Pipes: Feature zinc coating of 80-120 microns for general applications.

- Heavy Galvanized Earthing Pipes: With zinc coating of 120-150 microns for corrosive soil conditions.

- Copper-Bonded Earthing Pipes: Steel core with permanent molecular bond of copper for superior conductivity and corrosion resistance.

- Perforated GI Earthing Pipes: Feature strategically placed holes to allow for better contact with earth-enhancing compounds.

All our GI earthing pipes are manufactured according to IS:3043 and IS:2629 standards, ensuring consistent quality and reliable performance. As a leading GI earthing pipe manufacturer in Kolkata, we also offer customized solutions to meet specific project requirements and soil conditions.

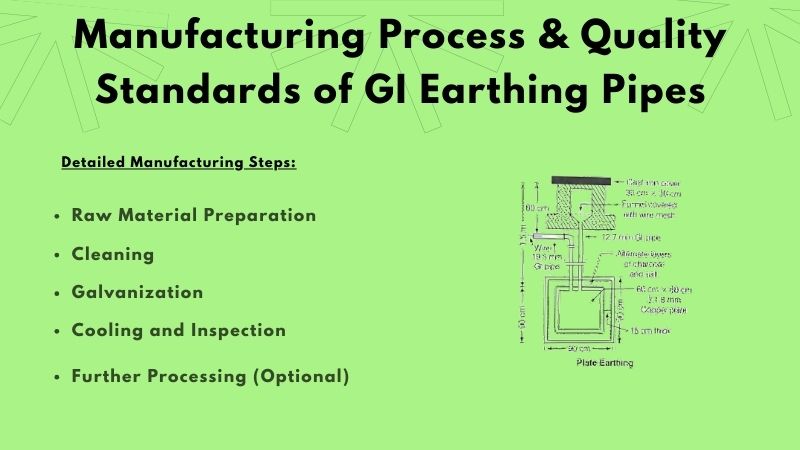

Manufacturing Process & Quality Standards of GI Earthing Pipes

The manufacturing process of high-quality GI earthing pipes involves several critical steps that ensure optimal electrical conductivity and long-term performance:

- Raw Material Selection: High-grade low-carbon steel with precise chemical composition is selected to ensure optimal electrical conductivity.

- Forming and Welding: The steel is formed into a tubular shape and welded along the seam using advanced welding technologies that maintain structural integrity.

- Surface Preparation: The pipes undergo thorough cleaning through acid pickling and fluxing to remove impurities, scale, and oxides before galvanization.

- Hot-Dip Galvanization: Pipes are immersed in a bath of molten zinc at approximately 450°C, forming a metallurgically bonded zinc coating that penetrates the steel surface.

- Cooling and Passivation: Controlled cooling followed by chromate passivation treatment to enhance corrosion resistance.

- Threading and Finishing: Precision threading at one or both ends to facilitate connections with couplers, clamps, or other earthing accessories.

- Testing: Rigorous testing including conductivity tests, zinc coating thickness measurements, and dimensional verification.

Quality Control Measures for Earthing Pipes

As a reputable GI earthing pipes supplier in Kolkata, we maintain strict quality control throughout the manufacturing process:

- Raw Material Testing: Chemical composition analysis to ensure optimal electrical conductivity

- Welding Quality Control: Ultrasonic testing of welds to ensure structural integrity

- Zinc Coating Measurement: Using advanced instruments to ensure uniform coating thickness of 80-150 microns as per application requirements

- Electrical Conductivity Testing: Verification of electrical resistance values to ensure effective grounding performance

- Dimensional Verification: Ensuring all pipes meet specified dimensions and tolerances for proper installation

- Corrosion Resistance Testing: Salt spray tests to verify long-term performance in challenging environments

Our GI earthing pipes comply with multiple standards including IS:3043 (Indian Standard for Earthing), IS:2629 (Hot-Dip Galvanizing), and IEEE 80 (Grounding of Substations), ensuring they meet the highest safety and performance requirements.

Applications of GI Earthing Pipes: Critical Safety Infrastructure

GI earthing pipes are essential components in electrical safety systems across numerous sectors:

Power Generation and Distribution:

- Power plants and generating stations

- Electrical substations and switching yards

- Transmission towers and distribution networks

- Renewable energy installations (solar and wind farms)

Industrial Applications:

- Manufacturing facilities and process plants

- Oil and gas installations

- Chemical and pharmaceutical plants

- Mining operations and metal processing facilities

Commercial and Residential:

- High-rise buildings and commercial complexes

- Data centers and telecommunications facilities

- Hospitals and healthcare institutions

- Educational institutions and government buildings

- Residential apartments and housing complexes

Infrastructure and Transportation:

- Airports and railway stations

- Highway lighting and traffic control systems

- Bridges and toll plazas

- Water and wastewater treatment facilities

As a trusted GI earthing pipe manufacturer in Kolkata, we supply high-quality earthing solutions for all these applications, ensuring electrical safety and regulatory compliance in every installation.

Advantages of GI Earthing Pipes: Superior Safety & Performance

GI earthing pipes offer numerous advantages that make them the preferred choice for electrical grounding systems:

- Excellent Electrical Conductivity: Low-carbon steel core provides efficient path for fault currents to dissipate into the earth.

- Superior Corrosion Resistance: Hot-dip galvanized coating provides long-term protection against soil corrosion, extending service life to 15-20 years or more.

- Mechanical Strength: Robust construction withstands driving into various soil types and resists physical damage during installation and service.

- Cost-Effectiveness: Despite the initial investment, the long service life and minimal maintenance requirements make GI earthing pipes economical over time.

- Compliance with Standards: Meets or exceeds requirements of IS:3043, IEEE 80, and other international standards for electrical grounding.

- Versatility: Available in various diameters, thicknesses, and coating specifications to suit different soil conditions and application requirements.

- Easy Installation: Can be installed using conventional methods including manual driving, machine driving, or installation in pre-dug pits with earth-enhancing compounds.

- Compatibility: Works seamlessly with various earthing accessories including clamps, connectors, and earth enhancement materials.

As a leading GI earthing pipes supplier in Kolkata, we emphasize these advantages to help our customers implement reliable and compliant electrical safety systems for their facilities.

How to Choose the Right GI Earthing Pipe: Expert Guidelines

Selecting the appropriate GI earthing pipe for your electrical safety system involves considering several critical factors:

Key Selection Criteria:

- Soil Resistivity: Higher soil resistivity requires earthing pipes with larger diameters or multiple installations to achieve target resistance values.

- Fault Current Magnitude: Higher potential fault currents require earthing systems with greater current-carrying capacity.

- Soil Corrosivity: Highly corrosive soils necessitate pipes with heavier zinc coatings or copper-bonded options.

- Required Earth Resistance: Critical installations like substations typically require very low earth resistance values (less than 1 ohm), necessitating more robust earthing solutions.

- Installation Method: Consider whether pipes will be driven into the ground or installed in pre-dug pits with earth-enhancing compounds.

- Regulatory Requirements: Ensure compliance with local electrical codes and industry standards for your specific application.

- System Lifespan: Consider the expected service life of the installation and select earthing pipes with appropriate durability.

Recommended GI Earthing Pipe Specifications by Application:

We offer specialized GI earthing pipes tailored to different applications:

- Residential Buildings: 25-40mm diameter, 2.0-2.5m length, 80-100 microns zinc coating

- Commercial Buildings: 40-50mm diameter, 2.5-3.0m length, 100-120 microns zinc coating

- Industrial Facilities: 50-80mm diameter, 3.0m length, 120-150 microns zinc coating

- Power Substations: 80-100mm diameter, 3.0m length, 120-150 microns zinc coating

- Telecommunications: 40-50mm diameter, 3.0m length, 100-120 microns zinc coating

As experienced GI earthing pipe manufacturers in Kolkata, we provide expert consultation to help you select the most suitable earthing solution for your specific requirements, ensuring optimal safety and compliance.

Why Choose Usha Metals as Your GI Earthing Pipes Supplier in Kolkata

When looking for a reliable GI earthing pipes supplier in Kolkata, Usha Metals stands out for several compelling reasons:

- Premium Quality: All our GI earthing pipes are manufactured using high-grade raw materials and advanced production techniques, ensuring superior conductivity and corrosion resistance.

- Comprehensive Range: We offer a complete range of earthing solutions including standard GI pipes, copper-bonded pipes, perforated pipes, and all necessary accessories.

- Competitive Pricing: Our efficient manufacturing processes and economies of scale allow us to offer high-quality products at competitive market rates.

- Technical Expertise: Our team includes electrical engineers and earthing specialists who can provide expert guidance on system design and installation.

- Customization Capabilities: We can customize earthing pipes according to specific project requirements, including non-standard sizes and special coating specifications.

- Stringent Quality Control: Every pipe undergoes rigorous testing for conductivity, coating thickness, and dimensional accuracy to ensure compliance with relevant standards.

- Prompt Delivery: We maintain extensive inventory and efficient logistics to ensure timely delivery across Eastern India and beyond.

- Comprehensive Documentation: We provide complete technical documentation including test certificates, compliance declarations, and installation guidelines.

- After-Sales Support: Our technical team remains available for post-installation support, testing, and troubleshooting.

As a trusted GI earthing pipe manufacturer in Kolkata, we have built a reputation for reliability, quality, and technical excellence, making us the preferred partner for electrical contractors, industrial facilities, and infrastructure projects throughout Eastern India.

Frequently Asked Questions About GI Earthing Pipes

What is the difference between GI pipes and GI earthing pipes?

While both are galvanized iron pipes, GI earthing pipes are specifically designed for electrical grounding applications with optimized electrical conductivity, appropriate wall thickness, and often feature precision threading for earthing connections. Standard GI pipes are primarily designed for fluid transport and may not meet the specific requirements for electrical grounding systems.

What is the typical lifespan of a GI earthing pipe?

With proper installation in normal soil conditions, quality GI earthing pipes can last 15-20 years or more. The lifespan depends on factors such as soil corrosivity, moisture content, installation method, and the thickness of the zinc coating. In highly corrosive soils, copper-bonded earthing pipes may be recommended for extended service life.

How do I know if my earthing system is working properly?

A properly functioning earthing system should have an earth resistance value that meets the requirements for your specific application (typically less than 5 ohms for residential, less than 2 ohms for commercial, and less than 1 ohm for critical installations). This can be verified using an earth resistance tester. Regular testing and maintenance are recommended to ensure continued effectiveness.

Can GI earthing pipes be used in all soil types?

GI earthing pipes can be used in most soil types, but their effectiveness varies with soil resistivity. In high-resistivity soils (sandy or rocky terrain), additional measures may be necessary, such as using earth-enhancing compounds, increasing pipe length, or installing multiple earthing points. For highly corrosive soils, pipes with heavier zinc coatings or copper-bonded options are recommended.

What is the recommended maintenance for GI earthing systems?

Recommended maintenance includes annual inspection of visible connections for corrosion or damage, periodic measurement of earth resistance (typically annually), ensuring adequate moisture around the earthing pipe during dry seasons, and checking for loose connections. In critical installations, more frequent testing may be required as per regulatory guidelines.

Conclusion: Your Trusted Partner for Quality GI Earthing Pipes in Kolkata

GI earthing pipes remain the backbone of reliable electrical safety systems across residential, commercial, and industrial applications. As a leading GI earthing pipes supplier in Kolkata, Usha Metals is committed to providing high-quality grounding solutions that ensure the safety of people, equipment, and infrastructure.

Our comprehensive range of GI earthing pipes in Kolkata is manufactured to meet or exceed relevant standards, providing the perfect balance of electrical conductivity, corrosion resistance, and mechanical strength. Whether you're working on a residential project, commercial building, industrial facility, or critical infrastructure, our earthing solutions deliver reliable performance and regulatory compliance.

With our technical expertise, quality manufacturing processes, and commitment to customer satisfaction, we have established ourselves as the best GI earthing pipe supplier in Kolkata. Contact Usha Metals today to discuss your electrical grounding requirements and experience the difference that a specialized earthing solution provider can make to your projects.

This article was created in partnership with Koncept Solution, a leading industrial content development agency specializing in technical documentation and industry insights.